Don’t Let Rust Wreck Your Home: Essential Tips to Stop Electrical Panel Corrosion!

By: Matt Pinkston - Master Electrician | October 23, 2025 | (Updated November 2025)

Written by Matt Pinkston, Operations Manager at

Bright Electric— a licensed electrical contractor serving Evansville, IN for over 30 years.

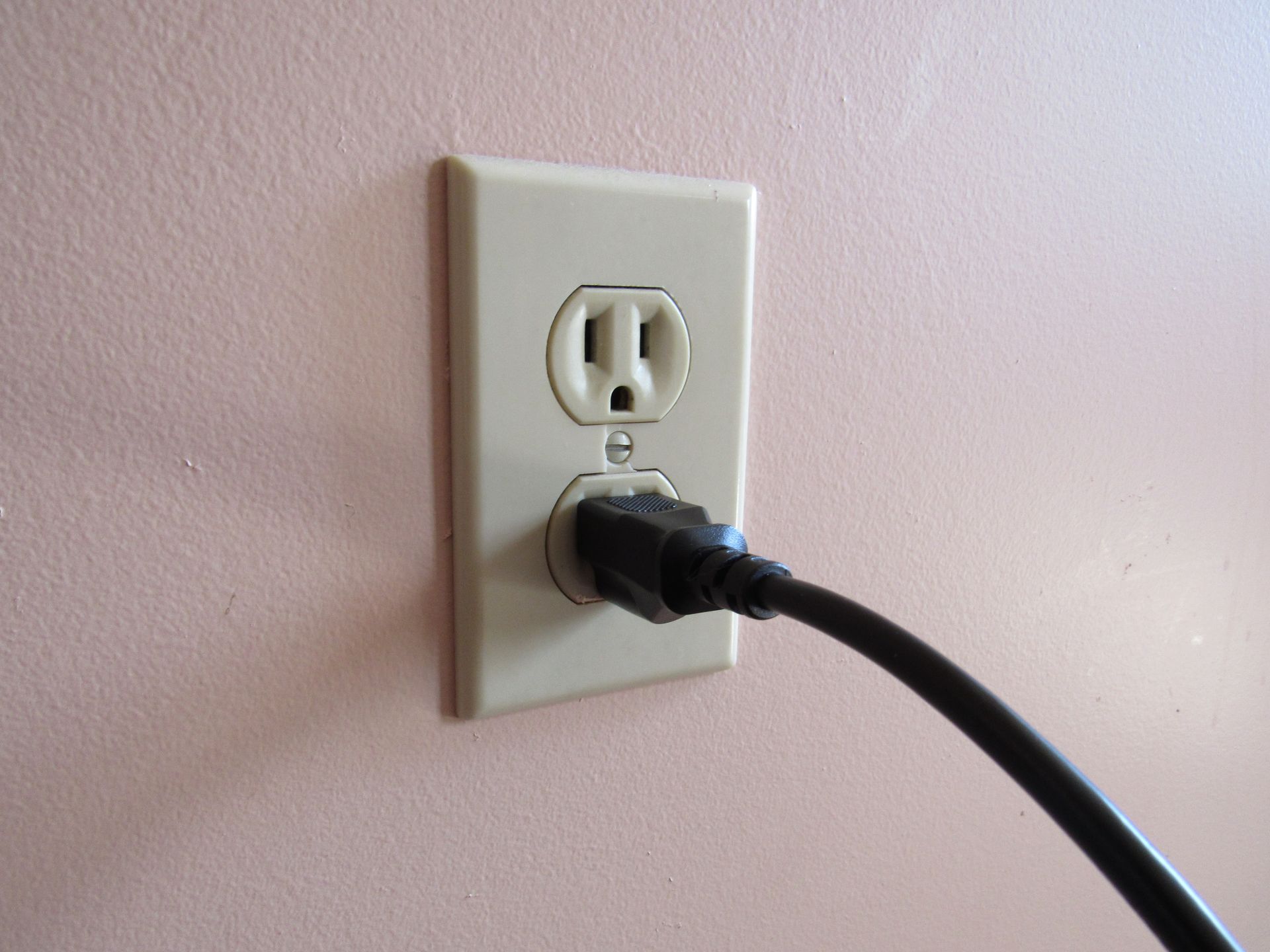

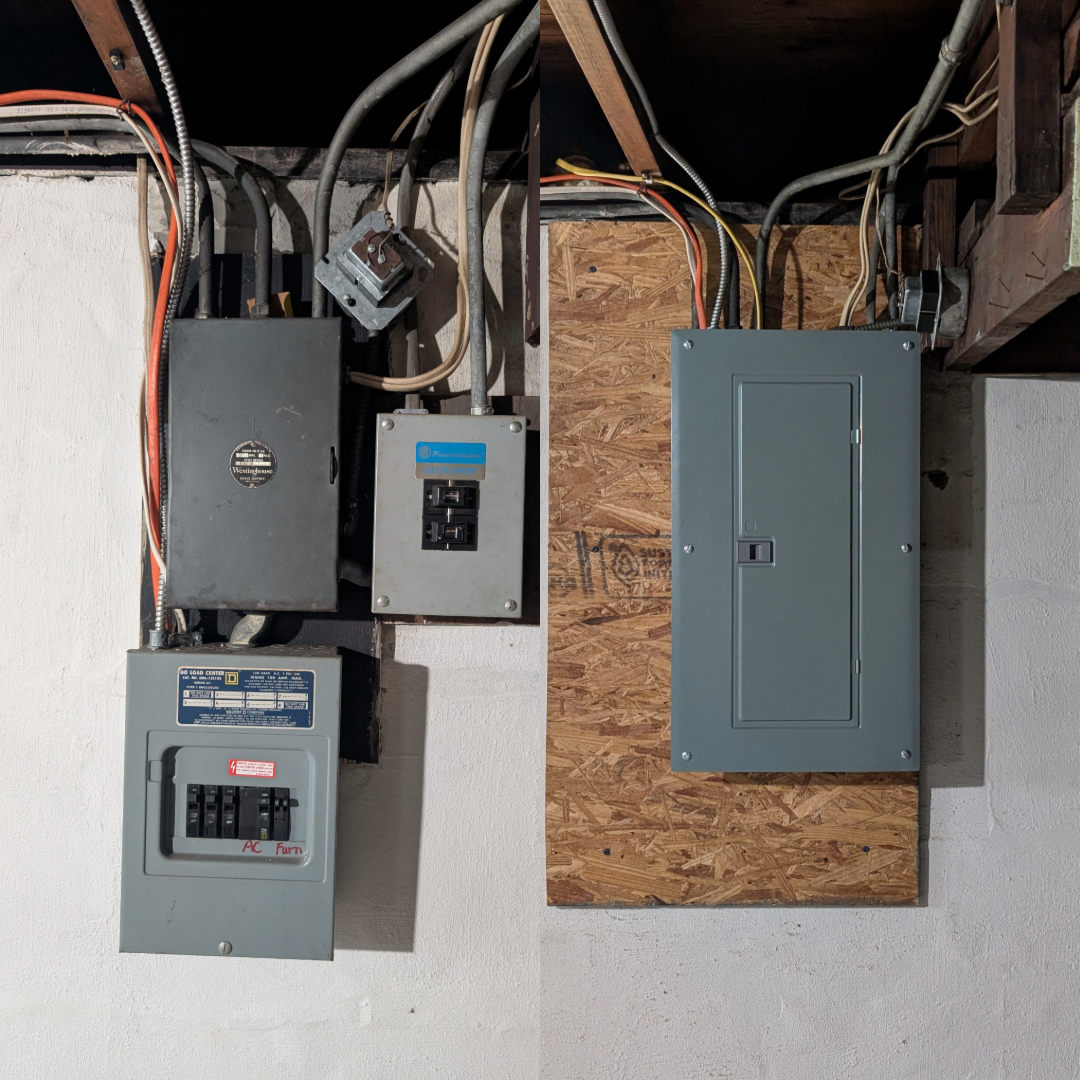

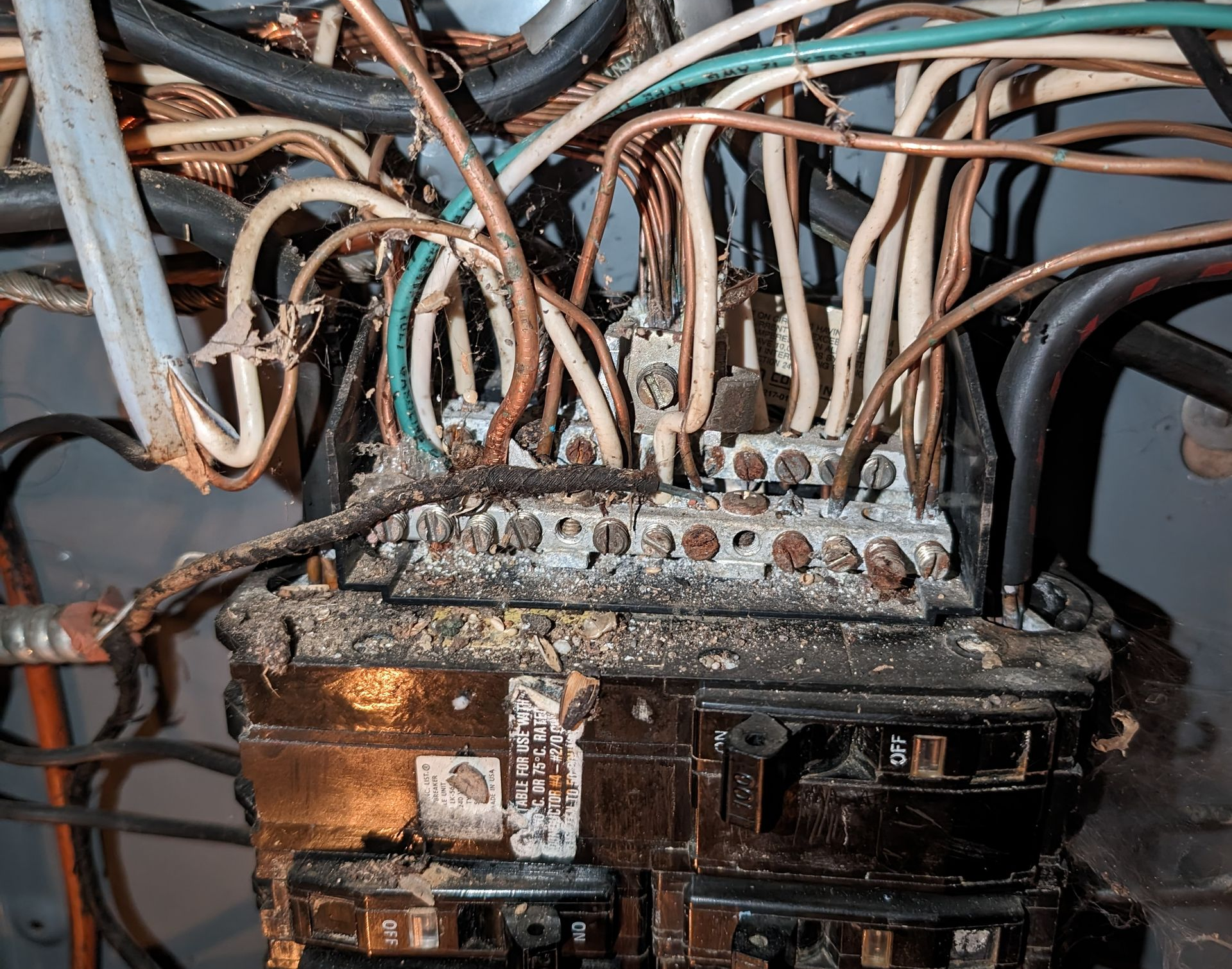

Electrical panels are the heart of your home's electrical system, distributing power safely to every part of your house. But when rust and corrosion creep in, they can compromise safety and performance. A corroded electrical panel can lead to increased resistance, heat buildup, and even electrical fires if left untreated.

This complete guide explains what causes electrical panel corrosion, how to spot it early, and what you can do to stop it—plus the best products to help protect your system for years to come.

What Causes Corrosion in Electrical Panels (and Why It Happens)

Corrosion happens when moisture meets metal inside or around your breaker box. Here are the most common causes:

Condensation

When warm, moist indoor air meets a cold panel or conduit, condensation can form inside. This is especially common where the conduit from the outdoor meter enters the home.

Humidity

Basements and utility rooms often have high humidity levels, which accelerate oxidation on breakers, bus bars, and grounding terminals.

Leaks

Roof or plumbing leaks can drip down walls and into electrical panels. Even slow leaks can create serious corrosion problems over time.

Signs of a Corroded Electrical Panel You Shouldn’t Ignore

It’s not always easy to see corrosion immediately—but these are clear warning signs:

- Visible rust or discoloration on the breaker box cover or screws

- Flickering lights throughout the house (caused by poor connections)

- Intermittent power loss or tripped breakers without clear cause

- A burnt or metallic odor near the panel

If you notice any of these, it’s time to investigate before small rust spots turn into a serious hazard.

The Hidden Dangers of Panel Corrosion

Corrosion isn’t just cosmetic. Even minor corrosion in an electrical panel can be dangerous. As rust builds, it increases electrical resistance, forcing your system to work harder. That resistance generates excessive heat, which can:

- Damage wire insulation

- Weaken breaker contacts

- Increase the risk of electrical fires

Replacing or repairing corroded parts early prevents costly damage and keeps your home safe.

How to Prevent Electrical Panel Corrosion

The good news: prevention is simple with a few low-cost materials and regular attention.

Use Duct Seal

Apply duct seal where conduits enter the panel or meter—especially those that come in from outside the home. This simple step blocks humid air and prevents condensation inside the box.

- Recommended Product: Duct Seal Compound

Note: Avoid spray foam or general-purpose sealants. Only use products listed for electrical applications.

Control Humidity

If your electrical panel is in a basement or utility area, maintain humidity below 50%.

- Recommended Product: Dehumidifier for Basements

Monitor Moisture Levels

Keep a small hygrometer nearby so you can track humidity and catch issues early.

- Recommended Product: Digital Hygrometer

Schedule Regular Inspections

Have a licensed electrician inspect your electrical system every few years to check for corrosion, loose connections, or moisture entry points.

| Product | Purpose | Link |

|---|---|---|

| Duct Seal Compound | Seals conduit openings and blocks humid air | Duct Seal Compound on Amazon |

| Dehumidifier | Reduces moisture near basement panels | Basement Dehumidifier on Amazon |

| Digital Hygrometer | Monitors humidity levels over time | Digital Hygrometer on Amazon |

Affiliate Disclosure: As an Amazon Associate, Bright Electric may earn from qualifying purchases at no extra cost to you.

Why Addressing Corrosion Matters

Ignoring electrical panel rust doesn’t just risk system failure—it can jeopardize your safety.

Corroded panels increase resistance, heat, and potential arcing that may lead to electrical fires.

Preventive steps like sealing conduit openings, controlling humidity, and scheduling inspections cost far less than replacing a burned or unsafe panel.

Related Guides

- Electrical Panel Upgrade: When and Why to Replace Your Breaker Box

- Generator Inlet Installation: Safe Backup Power for Your Home

Frequently Asked Questions

Can I clean rust off my breaker panel myself?

Surface rust on the exterior can be wiped with a dry cloth, but never attempt to clean corrosion inside the panel. Internal damage should always be inspected by a licensed electrician.

What’s the best way to stop condensation in my electrical panel?

Seal outdoor conduit openings with duct seal and use a dehumidifier near the panel—especially in basements or humid climates.

Does corrosion in an electrical panel mean I need a full replacement?

Not always. Minor surface rust may be manageable, but corrosion on bus bars or breakers often means replacement is the safest route.

Keep Your Home Safe

Electrical corrosion doesn’t happen overnight—but once it starts, it spreads quickly.

Protect your system now with simple preventive steps and reliable products that keep moisture out for good. If corrosion is severe, you may need an

Electrical Panel Upgrade.

Mr. Bright says: “When in doubt, don’t take risks with live panels. Leave the electrical work to licensed pros — your safety comes first!”

Bright Electric: helping homeowners stay safe, informed, and powered—wherever you live. “If you’re in the

Evansville, IN area, Bright Electric can inspect and replace your electrical panel safely and professionally.

Written & Reviewed by:

Matt Pinkston — Master Electrician (Vanderburgh County License #29714)

Operations Manager at Bright Electric

27+ years of electrical experience in Evansville and the Tri-State area.

Specializes in residential and commercial electrical work, NEC code compliance, and modern electrical safety standards.